The Napier Nomad, a British diesel aircraft engine, was developed and manufactured by Napier & Son in 1949. This innovative engine design combined a piston engine with a turbine to recuperate energy from the exhaust, aiming to enhance fuel efficiency.

Two distinct models of the Nomad were tested: the Nomad I, a complex version utilizing two propellers driven by mechanically independent stages, and the Nomad II, which employed the turbo-compound principle to couple both parts, powering a single propeller.

The Nomad II achieved notably low specific fuel consumption figures, unprecedented at the time. However, despite these advancements, the Nomad project was discontinued in 1955 after an investment of £5.1 million in development.

The aviation industry’s focus had shifted predominantly to turboprop designs, leading to dwindling interest in the Nomad’s technology.

Contents

Background

In 1933, Napier expanded its expertise in diesel engines by acquiring licenses to produce the Junkers Jumo 204 and 205 aircraft engines, known as the Culverin (E102) and Cutlass (E103). While these engines didn’t achieve commercial success, the experience provided Napier with invaluable knowledge in two-stroke, high-powered diesel engines.

Towards the end of 1944, the British Ministry of Aircraft Production (subsequently the Ministry of Supply, MoS) laid out specifications for a 6,000 hp (4,474 kW) economical aircraft engine for large, long-range aircraft.

Harry Ricardo, a renowned engine designer, proposed that a combination of a two-stroke diesel engine and a gas turbine would yield a powerful, compact, and fuel-efficient aircraft engine.

Read More: Frank Whittle the King of the Jet Engine

Napier, building on Ricardo’s idea and their own experience with diesel engines, proposed the E124 for the 6,000 hp engine. This concept was an H-24 diesel engine, with a displacement of about 4,575 cubic inches (75 L), integrated with an axial flow recovery turbine.

Exhaust-Driven Turbine

The engine’s design featured upper and lower cylinder banks set at a 150-degree angle, with left and right banks at 30 degrees to allow space for exhaust manifolds.

Although single- and twin-cylinder tests, as well as trials on the axial-flow compressor, had commenced, Napier concluded the engine would have limited market appeal and discontinued the project in 1946.

The E124 project, while not realized, paved the way for the development of a new engine, the E125 Nomad I, aimed at achieving minimal fuel consumption under any operational condition. Preliminary design work on the Nomad I began in 1945, with MoS backing by 1946.

Essentially, the Nomad I was a modified version of half of the H-24 engine, with an improved recovery turbine.

It was a liquid-cooled, horizontally-opposed, 12-cylinder, two-stroke, valveless diesel engine featuring a gear-driven, two-speed supercharger and an exhaust-driven turbine coupled to a compressor at the engine’s base. The compressor alone couldn’t achieve the desired high level of boost, necessitating the inclusion of a supercharger to meet the design objectives.

Nomad I

The initial design of the Nomad (E.125), also known as Nomad 1, was an intricate piece of engineering, essentially combining two engines into one. The first component was a turbo-supercharged two-stroke diesel engine, somewhat akin to half of a Napier Sabre’s H-24.

Read More: Weird Wings, Republic XF-91 Thunderceptor

Below this diesel engine were the rotating elements of a turboprop engine, based on the Naiad design, which powered the front propeller of a contra-rotating pair.

To generate higher boost, a centrifugal supercharger driven by the crankshaft was incorporated. This supercharger not only increased the engine’s power but also provided the necessary scavenging for starting the engine from a stationary position. During takeoff, additional fuel was injected into the rear turbine stage for extra power, which was then reduced once the aircraft reached cruising altitude.

Throughout 1948, the compressor and turbine components of the Nomad were put through tests, leading up to the complete unit being run in October 1949. The prototype was fitted into an Avro Lincoln heavy bomber for flight tests, making its maiden flight in 1950 and later appearing at the Farnborough Air Display on 10 September 1951.

Although the intricate design of the engine was prone to reliability issues, the Nomad I demonstrated impressive fuel efficiency when operating optimally. Concurrent with the testing of the Nomad I, work was underway on a revised, more streamlined version of the engine.

Read More: Convair YB-60 the B-52s Competition

This updated model was designated as the E145 Nomad II. The design of the Nomad II incorporated insights gained from the experiences with the Nomad I, as well as advancements in axial compressor technology, reflecting a continuous process of refinement and improvement.

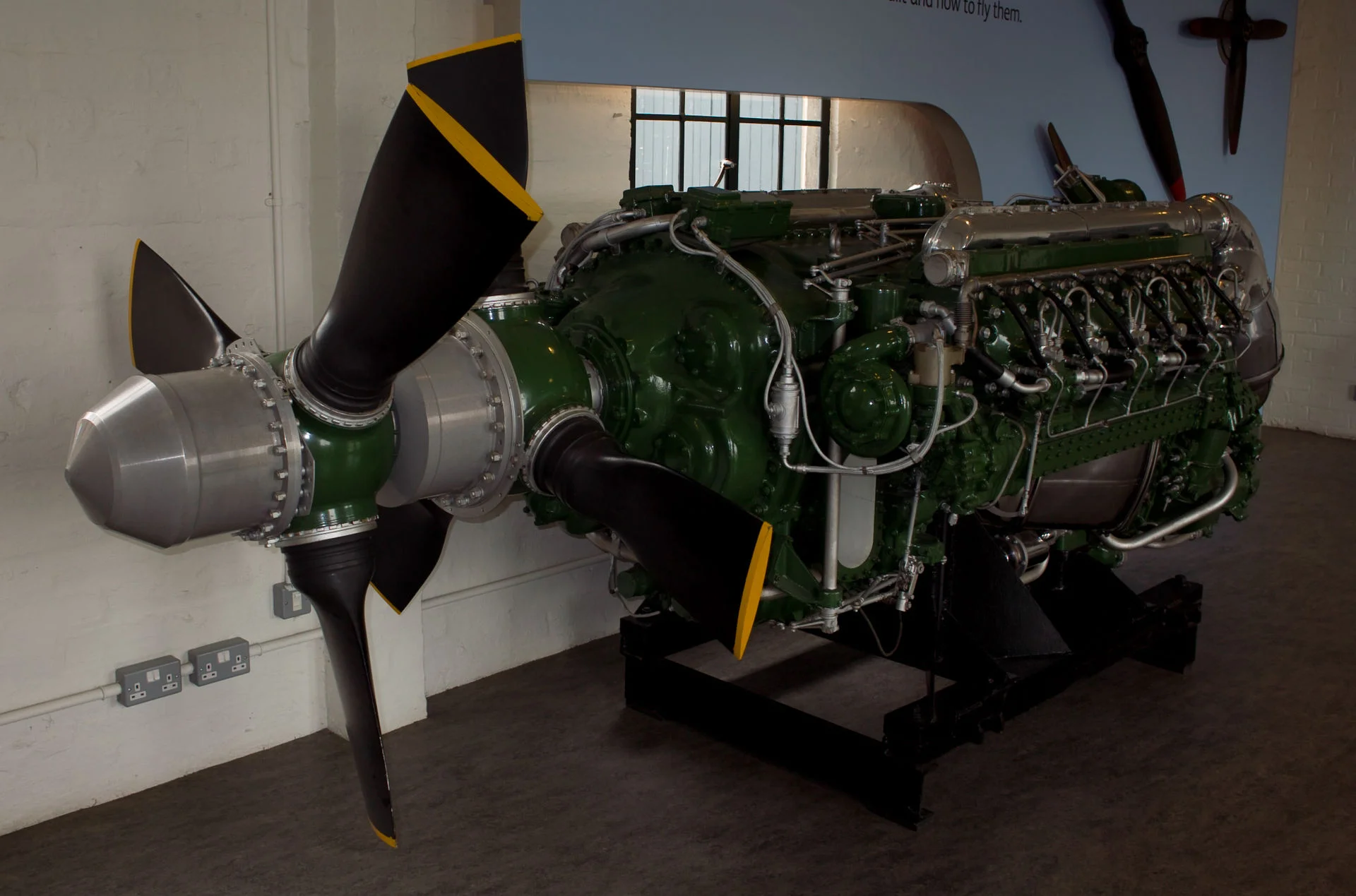

The prototype of the Nomad I is currently exhibited at the National Museum of Flight at East Fortune Airfield in Scotland, serving as a testament to this innovative period in aviation engineering.

Nomad II

Before the Nomad I engine was fully operational, its successor, the Nomad II (E.145), also known as Nomad 6, had already been conceptualized and designed. In this updated version, an additional stage was incorporated into the axial compressor/supercharger.

This enhancement effectively eliminated the need for the separate centrifugal component and the intercooler, streamlining the engine’s design and functionality.

The enhanced axial flow compressor of the Nomad II was a significant upgrade, measuring 10.88 inches (276 mm) in diameter and suspended beneath the engine using four flexible mounts.

This compressor featured 12 stages, achieving a maximum pressure ratio of 8.25 to 1, and was capable of handling a maximum air mass flow of 13 lb/sec (5.9 kg/sec). Its forward-facing inlet was designed to maximally utilize ram air.

Read More: He-274 High-Altitude German Bomber

To optimize airflow at lower speeds, the pitch of the compressor’s inlet guide vanes was automatically adjustable. The compressor’s first five stages were equipped with cobalt-steel blades, while the remaining seven stages utilized aluminum-bronze blades, enhancing its efficiency and durability.

Six Ports Per Cylinder

The Nomad II also saw improvements in its loop-scavenged system, compared to the Nomad I. Air from the compressor was directed forward through a manifold located beneath each cylinder bank. This pressurized air then entered the redesigned cylinder banks, flowing through guide vanes and entering each cylinder via eight intake ports.

These ports were arranged as two sets of four, positioned on the upper sides of the cylinder wall (the top side of the engine). The intake ports were specially designed to direct the airflow towards the hemispherical combustion chamber, facilitating circulation back towards the piston and the uncovered exhaust ports.

Regarding the exhaust system, the Nomad II featured six ports per cylinder, comprising three larger ports, each accompanied by a smaller port located below, nearer the piston. These exhaust ports were situated on the lower side of the engine, closer to the combustion chamber than the intake ports. This arrangement was crucial in optimizing the engine’s efficiency and power output.

Roared to Life

When observed from the rear of the engine, the propeller was designed to rotate in a counterclockwise direction. At the front of the engine, within the reduction gear housing, the crankshaft transmitted power to the propeller shaft through a mechanism involving four pinions.

Read More: Wasserfall the Surface-to-Air Missile

The Nomad II engine first roared to life in December 1952 and had clocked up 350 hours by mid-1954. It underwent a series of rigorous bench tests, including trials with a 13 ft (3.96 m) diameter constant-speed, reversible-pitch propeller. Interestingly, running the engine on different fuels such as diesel, kerosene, or jet fuel (wide-cut gasoline) showed little variation in power output.

Some tests even suggested that it could achieve a specific fuel consumption (sfc) as low as 0.326 lb/ehp/hr (198 g/kW/h), particularly evident at an altitude of 22,250 ft (6,782 m) with the engine generating 2,027 ehp (1,511 kW) at 1,750 rpm.

Read More: Supermarine P.B.31E Nighthawk Zeppelin Hunter

The Nomad II was capable of maintaining its takeoff power up to 7,750 ft (2,362 m) and could sustain a constant boost, power, and sfc up to an altitude of 25,000 ft (7,620 m). At sea level, the turbine developed 2,250 hp (1,678 kW), although 1,840 hp (1,372 kW) of this was used to power the compressor. The engine experienced a 2% power reduction for every 20° F (11° C) increase in air temperature.

Avro Shackleton

An interesting feature of the Nomad was that only 70% of the air passing through the cylinders was burnt, leading to experiments with fuel injection into the exhaust manifold, which resulted in an enhanced output of 4,095 ehp (3,054 kW) for an sfc of .374 lb/hp/hr (227 g/kW/h).

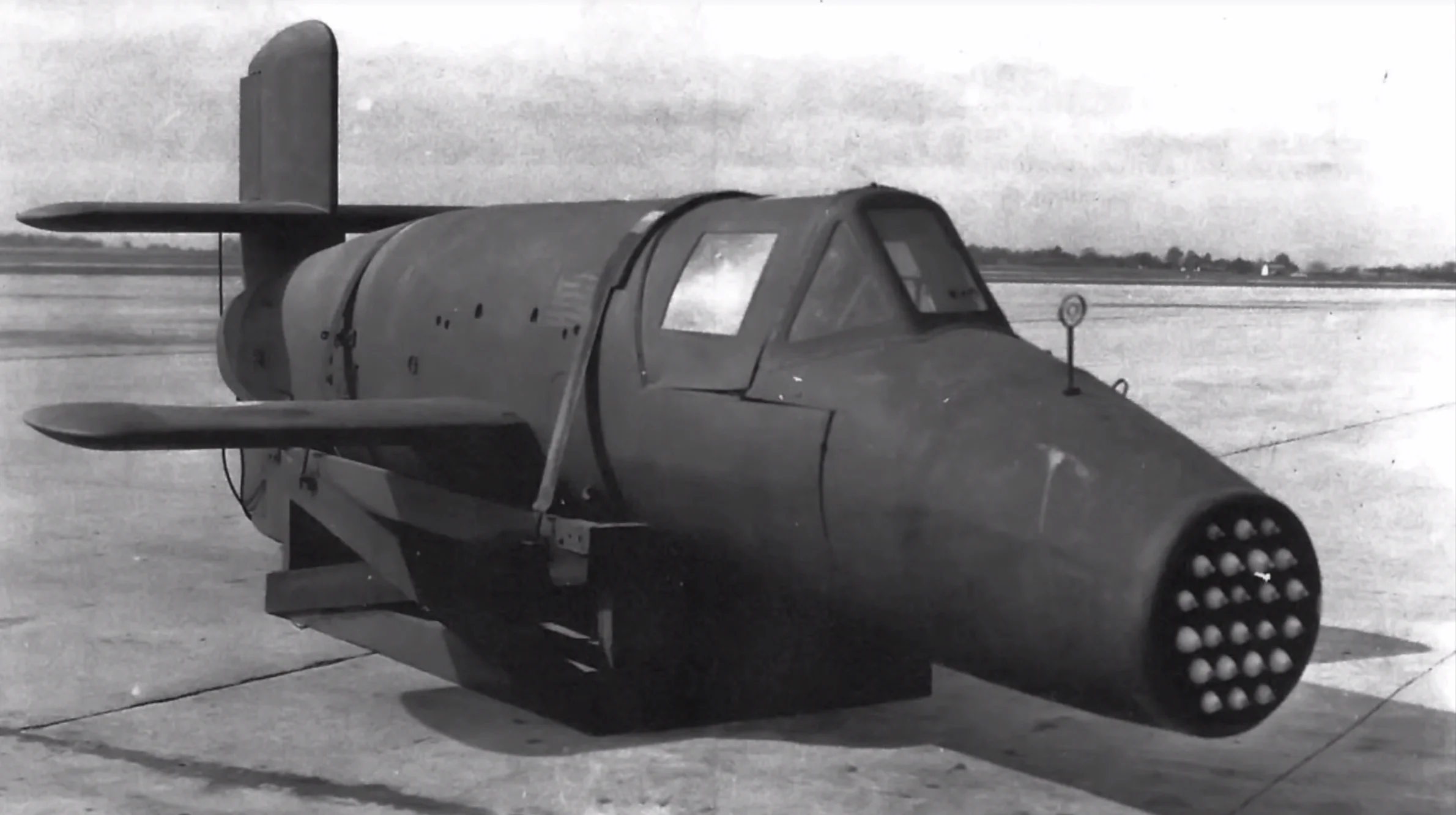

Napier proposed fitting the Nomad II engines into an Avro Shackleton maritime patrol aircraft, replacing the outer two Rolls-Royce Griffons, for flight tests. In October 1952, the MoS loaned a prototype Shackleton (VW131) to Napier for this purpose.

The aircraft arrived at Napier’s facility in Luton on 16 January 1953. Initial tests with dummy engines and subsequent vibration assessments were conducted in April 1954. The installation of the Nomad II engines was sleek and aerodynamic, but there were delays in receiving flight-cleared engines.

Read More: Horton: FMA I.Ae. 37 a Prototype Jet Fighter

Although two Nomad II engines were eventually installed and ground tests were conducted, the program was halted in April 1955 before any flight tests could occur. Despite the Nomad II’s exceptional fuel efficiency and its being simpler, lighter, smaller, and more powerful than the Nomad I, there was limited demand for the engine.

Napier preserved the Nomad data for some time, hoping for renewed interest that might reignite development, but this never materialized.

Prior to the project’s cancellation in 1955, the E173 Nomad III was conceptualized as a further advancement of the engine. This iteration included fuel injection into the exhaust manifold and an air-to-water aftercooler between the compressor and the cylinders.

Turboprops and Turbojets

This version had a wet takeoff rating of 4,500 ehp (3,356 kW) at 2,050 rpm, which equated to 4,412 shp (3,290 kW) combined with 230 lbf (1.021 kN) of thrust from the turbine. The Nomad III was slightly heavier than its predecessor, weighing in at 3,750 lb (1,701 kg), yet a complete engine was never constructed.

Read More: Fokker D.XXIII – A Promising Twin-Engine Fighter Prototype

While the Nomad showcased remarkable fuel efficiency and power-to-weight ratio, it was ultimately eclipsed by the development of turboprops and turbojets. Financial constraints and the already significant investment of £5.1 million in the Nomad program were factors in its discontinuation.

In scenarios like the Avro Shackleton, opting for Griffon engines was more cost-effective than further developing the Nomad. For other projects, the long-term potential of turboprops was more appealing. Despite the Nomad’s design being optimized for cruising speeds around 345 mph (556 km/h), turbojets were offering significantly higher cruise speeds, surpassing any other type of aircraft engine at the time.

However…

By 1954, interest in the Nomad engine had significantly diminished. The decline was further cemented when the only project based on it, the Avro Type 719 Shackleton IV, was cancelled. Consequently, development on the Nomad engine ceased in April 1955, after a substantial investment of £5.1 million.

Read More: Zveno Project an Incredible Aviation Concept

The engine had also been considered for the Canadair Argus, a maritime patrol aircraft being developed for the Royal Canadian Air Force. However, this project eventually opted for the Wright R-3350 engine, which was precisely the type of design the Nomad had aimed to surpass in performance.

For those interested in aviation history, a Nomad II engine is on display at the Steven F. Udvar-Hazy Center in Virginia, serving as a testament to this ambitious but ultimately unrealized chapter in aircraft engine development.